Campbell Hausfeld WS0900 Instructions d'exploitation

Naviguer en ligne ou télécharger Instructions d'exploitation pour Système de soudage Campbell Hausfeld WS0900. Campbell Hausfeld WS0900 Operating instructions Manuel d'utilisatio

- Page / 12

- Table des matières

- DEPANNAGE

- MARQUE LIVRES

- Shielded Metal 1

- Arc Welder 1

- General Safety (Con’t) 2

- Installation 3

- Assembly 3

- Operation 4

- Assembly (Con’t) 4

- Operation (Con’t) Maintenance 5

- Welding Guidelines 5

- Arc Welding Basics 6

- (Continued) 7

- Troubleshooting Chart - Welds 8

- Limited 5-3-1 Warranty 9

- WS0950, WS1000 and WS1020 11

- Glossary of Welding Terms 12

Résumé du contenu

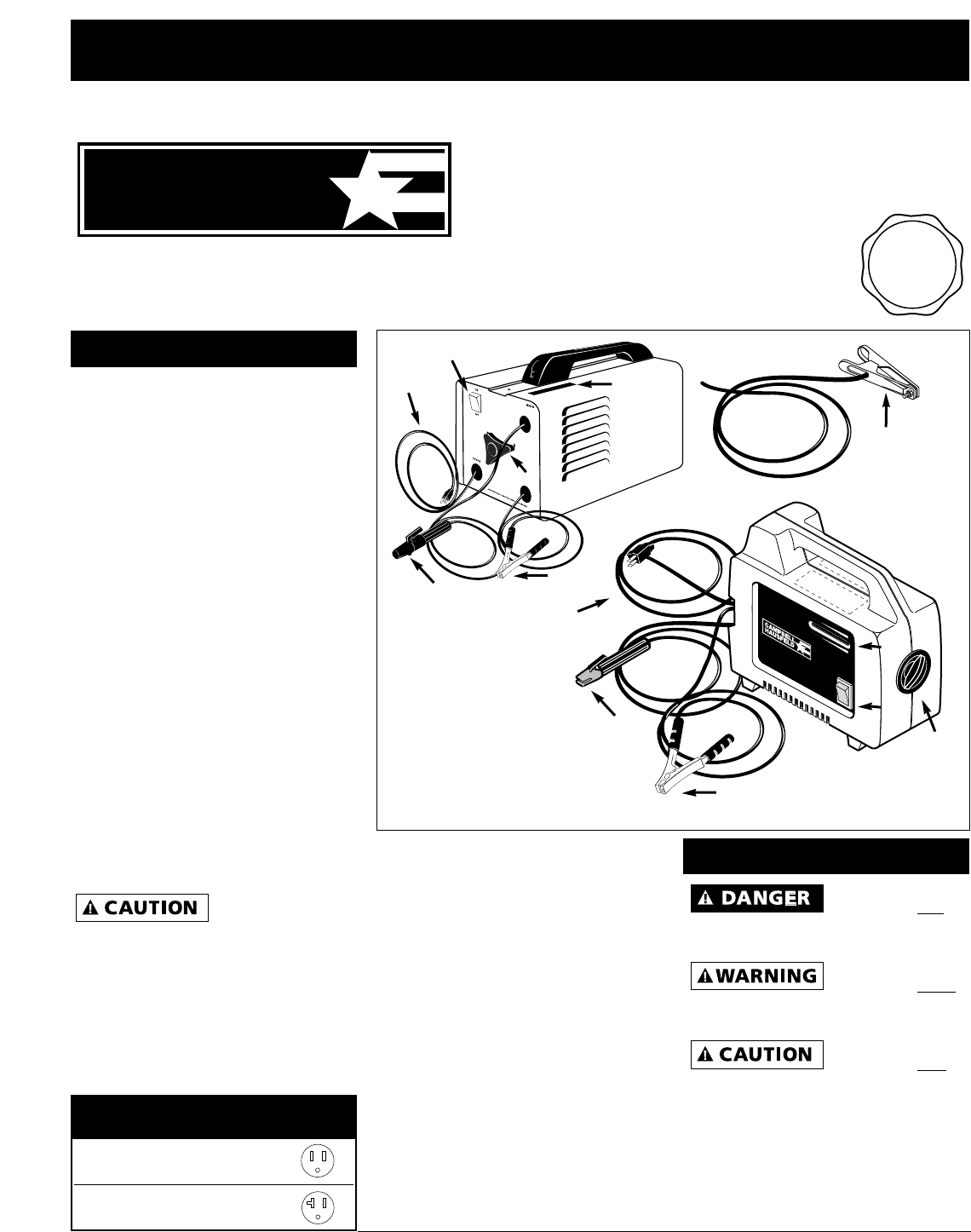

DECREASEINCREASE1234561245631 Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain th

1089121010713111234561 Electrode holder assembly - Cord not included (Includes reference numbers 2-7) WC200000AV 12 Electrode holder handle (Cord not

111 Electrode holder assembly - Cord not included (Includes reference numbers 2-7) WC200000AV 12 Electrode holder handle (Cord not included) WC200001A

12Shielded Metal Arc Welder Models WS0900, WS0950, WS1000 and WS1020Glossary of Welding TermsAC or Alternating Current - electriccurrent that reverses

2Shielded Metal Arc WelderAlways keep a fireextinguisher accessiblewhile performing arcwelding operations. ● Before starting or servicing anyelectric

Safe Practices For Occupational AndEducational Eye And Face ProtectionANSI Standard Z87.1, from AmericanNational Standards Institute, 1430Broadway, Ne

2. Insert filter lens.3. Attach the stiffeners over the pins onthe lens retainers (See Figure 5).4. To attach the handle, place shield ona flat surfac

5Models WS0900, WS0950, WS1000 and WS1020DUTY CYCLE / THERMOSTATICPROTECTIONWelder duty cycle is the percentage ofactual weld time that can occur in a

6Shielded Metal Arc Welder2. E-7014 FAST FILL• Smooth bead and fast deposition• Ideal for joints with poor fitup andgeneral repair workNOTE: E-6011 a

7Models WS0900, WS0950, WS1000 and WS1020Welding Guidelines (Continued)area (See Figure 10). When the speed istoo fast, the bead is narrow and beadrip

8Troubleshooting Chart - WelderSymptom Possible Cause(s) Corrective Action1. No power at receptacle2. Broken or damaged powercable1. Inadequate curren

9Supply Cable Replacement (Except WS0900)1. Disconnect the black, white and green wires from therelative terminals (A) and (B).2. Push the cable ancho

(40 pages)

(40 pages) (64 pages)

(64 pages)

Commentaires sur ces manuels